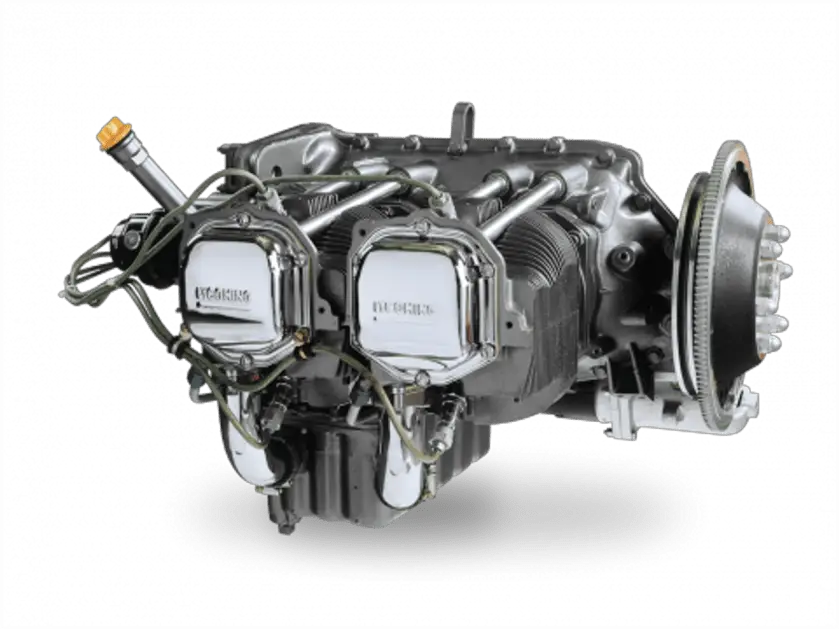

One of the best engines that were used for light aircraft and some types of racing aircraft.

The Lycoming O-290 is a four-cylinder, air-cooled, horizontally opposed piston engine designed for light aircraft.

Known for its reliability and simplicity, the O-290 was a popular choice for general aviation aircraft in the mid-20th century and remains respected among vintage aircraft enthusiasts.

History and Development

The Lycoming O-290 was introduced in the late 1940s as part of Lycoming’s family of horizontally opposed engines.

Designed to provide a reliable and efficient power source for light aircraft, the O-290 quickly became a favorite among aircraft manufacturers and pilots.

It was produced in several variants, each offering different performance characteristics to meet a range of aviation needs.

Lycoming O-290 Design and Features

The Lycoming O-290 is an air-cooled, four-cylinder engine with a horizontally opposed configuration. Key design features include:

- Displacement: 290 cubic inches (4.8 liters)

- Bore and Stroke: 4.875 inches (123.8 mm) bore and 3.875 inches (98.4 mm) stroke

- Block Material: Aluminum alloy for lightweight and durability

- Cylinder Heads: Cast aluminum with overhead valves

- Valvetrain: Overhead valve (OHV) with hydraulic lifters

- Fuel System: Carbureted, with a single updraft carburetor

- Ignition System: Dual magnetos for redundancy and reliability

Lycoming O-290 Specifications

Here are the detailed specifications for the Lycoming O-290 engine:

| Specification | Details |

|---|---|

| Manufacturer | Lycoming Engines |

| Production Years | Late 1940s – 1950s |

| Configuration | Horizontally opposed 4-cylinder |

| Displacement | 290 cu in (4.8 L) |

| Bore x Stroke | 4.875 in x 3.875 in (123.8 mm x 98.4 mm) |

| Compression Ratio | 7.00:1 to 8.50:1 (varies by model) |

| Power Output | 125 hp to 135 hp (93 kW to 101 kW) |

| Fuel Type | Aviation gasoline |

| Dry Weight | 250 lbs (113 kg) |

Lycoming O-290 Performance and Variants

The Lycoming O-290 came in several variants, each tailored for specific performance requirements:

- O-290: The standard version, typically producing around 125 hp.

- O-290-D: An upgraded variant with improved components, producing up to 135 hp.

- O-290-D2: A further improved version with enhanced performance and reliability.

- O-290-G: A ground power unit version used in stationary applications such as generators and pumps.

Applications

The Lycoming O-290 engine was used in a variety of light aircraft, including:

- Piper PA-18 Super Cub: Known for its ruggedness and versatility, the PA-18 was widely used for bush flying and general aviation.

- Piper PA-20 Pacer: A popular four-seat aircraft used for personal and utility flying.

- Piper PA-22 Tri-Pacer: A tricycle gear variant of the Pacer, offering improved ground handling.

Maintenance and Performance Upgrades

The Lycoming O-290 engine is known for its straightforward maintenance requirements and robust design. Regular maintenance includes oil changes, magneto checks, and valve adjustments. For enthusiasts looking to enhance performance, several upgrades are available:

- High-Compression Pistons: Increase power output and efficiency.

- Electronic Ignition Systems: Provide more reliable ignition and improved performance.

- Upgraded Carburetors and Intake Manifolds: Improve fuel flow and engine breathing.

- Lightweight Components: Reduce overall engine weight and improve performance.

Lycoming O-290 Price

The price of a Lycoming O-290 engine can vary widely based on its condition, whether it is new, rebuilt, or used, and any additional features or modifications. As of 2024, prices generally range from:

- Rebuilt Engines: $10,000 to $15,000 – These engines have been disassembled, inspected, and rebuilt to factory specifications.

- Used Engines: $5,000 to $10,000 – These engines are sold as-is and may require significant work to reach optimal condition.

- Performance-Built Engines: $15,000 to $20,000+ – These engines have been rebuilt with high-performance parts and modifications.

FAQs

1. What is the Lycoming O-290 engine?

The Lycoming O-290 is a four-cylinder, horizontally opposed, air-cooled aircraft engine. It was first introduced in the mid-20th century and became popular for its reliability and use in light aircraft such as the Piper PA-18 Super Cub and experimental aircraft.

2. What are the specifications of the Lycoming O-290 engine?

Key specifications of the Lycoming O-290 include:

- Configuration: Horizontally opposed, 4-cylinder

- Displacement: 290 cubic inches (4.75 liters)

- Horsepower: Typically between 125-135 HP

- Weight: Around 244 lbs (dry weight)

- Fuel Consumption: Approximately 8-9 gallons per hour (GPH)

3. What aircraft commonly use the Lycoming O-290?

The Lycoming O-290 was commonly installed in aircraft such as:

- Piper PA-18 Super Cub

- Piper PA-16 Clipper

- Piper PA-20 Pacer

- Various experimental and homebuilt aircraft

4. Is the Lycoming O-290 engine still in production?

No, the Lycoming O-290 is no longer in production. However, many are still in use today in vintage and experimental aircraft, and parts can be sourced from specialized suppliers and vintage aircraft communities.

5. What makes the Lycoming O-290 unique compared to other engines?

The O-290 is valued for its simple design, rugged construction, and excellent power-to-weight ratio. It offered a reliable and affordable engine solution for light aircraft in its era and continues to be a popular choice among homebuilders.

6. How does the Lycoming O-290 compare to the O-320?

The Lycoming O-290 and O-320 are similar in design, but the O-320 is slightly larger (320 cubic inches) and delivers more power (up to 160 HP). The O-320 is more widely used today, but the O-290 remains a classic choice for vintage aviation enthusiasts.

7. Can the Lycoming O-290 engine be used in experimental aircraft?

Yes, the Lycoming O-290 is a popular choice for experimental and homebuilt aircraft due to its affordability and availability. Builders often modify or rebuild these engines for specific performance needs.

8. What is the typical maintenance for a Lycoming O-290?

Regular maintenance includes:

- Oil changes every 25-50 hours or as recommended

- Spark plug inspections and replacement as needed

- Compression checks to monitor cylinder health

- Magneto servicing for reliable ignition

9. What is the Time Between Overhaul (TBO) for a Lycoming O-290 engine?

The recommended TBO for the Lycoming O-290 is typically around 1,500-2,000 flight hours, depending on operating conditions and adherence to maintenance schedules.

10. Are Lycoming O-290 parts still available?

Yes, parts for the Lycoming O-290 are available through aviation salvage yards, specialized suppliers, and online platforms dedicated to vintage aircraft maintenance.

11. What fuel does the Lycoming O-290 use?

The Lycoming O-290 is designed to run on aviation gasoline (avgas), typically 80/87 or 100LL grades. Some users may explore STCs (Supplemental Type Certificates) for mogas (automotive gasoline) use, depending on the application.

12. How much does a Lycoming O-290 engine cost?

The cost of a Lycoming O-290 varies based on condition, hours since the last overhaul, and whether it is new-old stock, used, or rebuilt. Prices generally range from $5,000 to $12,000.

13. What are some common issues with the Lycoming O-290?

While generally reliable, common issues can include:

- Cylinder wear over time

- Magneto or ignition system failures

- Oil leaks, often from aging gaskets

- Difficulty finding original parts for older models

14. Are there modern alternatives to the Lycoming O-290 engine?

Yes, modern alternatives include newer models from Lycoming, such as the O-320 and O-360, or engines from competitors like Continental. These offer better performance, modern materials, and compliance with current regulations.

15. Can the Lycoming O-290 engine be overhauled?

Yes, the Lycoming O-290 can be overhauled to restore performance and reliability. Overhaul services are offered by specialized aviation mechanics, or experienced owners may choose to undertake it themselves with proper certifications.

Leave a comment