The Electronic Centralized Aircraft Monitor (ECAM) doesn’t just diagnose crises—it dictates survival paths, guiding pilots through life-or-death procedures. This is how Airbus’s neural network has redefined emergency response since 1985.

What is ECAM? Aviation’s Digital Co-Pilot

ECAM (Electronic Centralized Aircraft Monitor) is Airbus’s integrated monitoring system that transforms complex aircraft data into actionable intelligence. Unlike traditional gauges, it:

- Consolidates hundreds of sensors into prioritized alerts

- Diagnoses failures using logic-driven analysis

- Prescribes step-by-step emergency checklists

- Projects system impacts on flight safety

Born on the Airbus A310, ECAM replaced paper checklists with what pilots call “the electronic bible”—slashing emergency response times by 70%. Today, it’s standard on all Airbus aircraft.

you’ll need this book before you start your Airbus A320 Type Rating “click here“

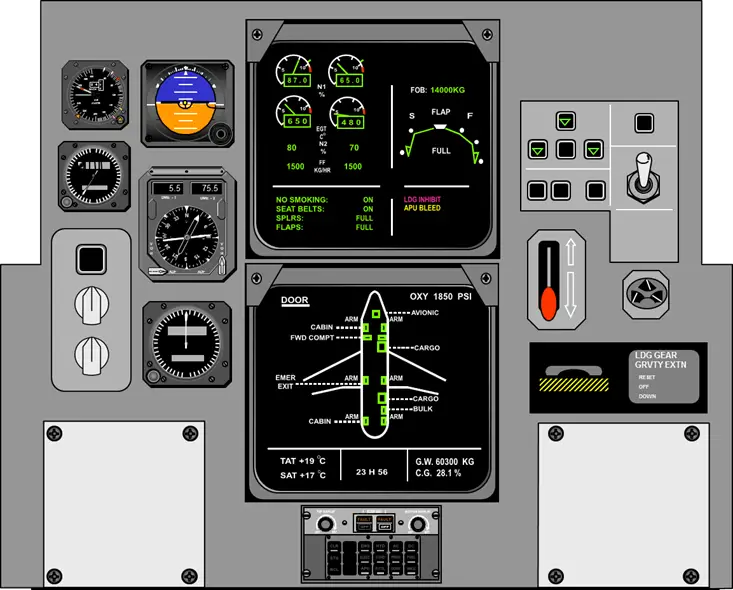

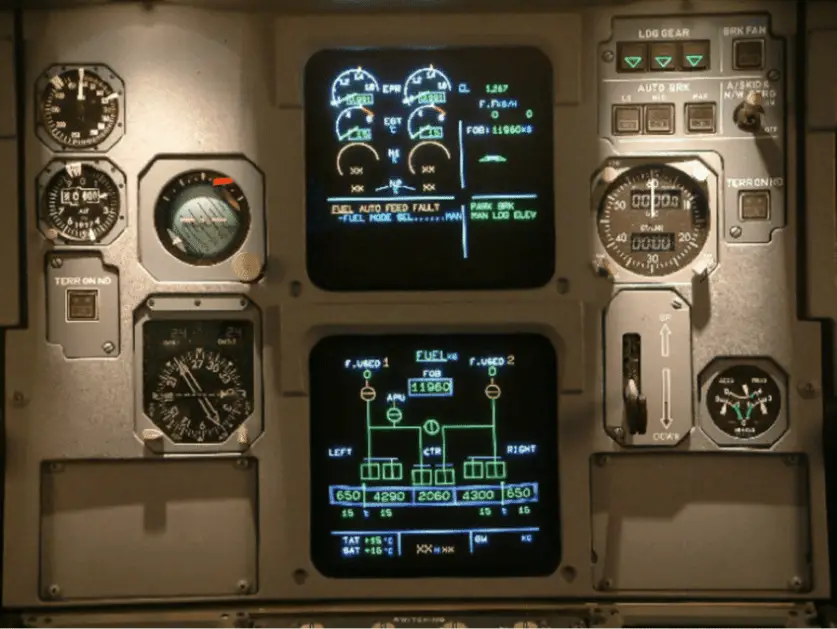

ECAM’s Command Center: Two Displays, One Mission

- Upper Display (E/WD – Engine/Warning Display)

- Real-time engine parameters (RPM, temperatures, fuel flow)

- Red warnings: Fire, cabin decompression (demand instant action)

- Amber cautions: System degradations (e.g., fuel imbalance)

- Lower Display (SD – System Display)

- Color-coded diagrams of hydraulic/electrical systems

- Predictive capabilities (e.g., “FUEL IMBALANCE IN 20 MIN”)

- Post-failure status summaries (“LAND ASAP” advisories)

Behind these screens, Flight Warning Computers and System Data Acquisition Concentrators cross-check data 100x/second. If primary systems fail, backups maintain critical monitoring—a redundancy that saved lives during multiple inflight emergencies.

ECAM’s Warning Hierarchy

ECAM classifies crises into three tiers with distinct responses:

| Level | Alert Type | Example Scenario | Pilot Response |

|---|---|---|---|

| 3 | Emergency (Red) | Engine fire | Immediate memory actions |

| 2 | Caution (Amber) | Bleed air failure | Action within 10 minutes |

| 1 | Advisory (Amber) | Redundant system loss | Monitor; no urgent action |

During a real dual sensor failure, ECAM escalated warnings from advisory to emergency in minutes—automatically disabling autopilot while generating stall recovery procedures.

ECAM’s Five Life-Saving Capabilities

- Predictive Diagnostics

Detects component fatigue before failure, triggering proactive maintenance. - Phase-Aware Intelligence

Tailors alerts to flight phases:- Takeoff: Suppresses non-critical warnings

- Cruise: Prioritizes fuel-saving reroutes

- Approach: Flags landing configuration errors

- Automated Forensics

Generates Post Flight Reports detailing every fault with timestamps. - Failure Correlation

Links related issues (e.g., sensor failure → autopilot dropout), preventing alarm floods. - Cyber Resilience

Encrypted databases and air-gapped networks protect critical systems.

When ECAM Saved the Day

▶ Dual Sensor Failure Incident

- Crisis: Iced sensors caused contradictory stall/overspeed warnings

- ECAM’s Response:

- Isolated faulty instruments

- Activated “Unreliable Airspeed” protocol

- Generated diversion coordinates

- Outcome: Safe landing despite degraded controls

▶ Major Engine Failure

- Crisis: Catastrophic engine damage with 80+ system failures

- ECAM’s Response:

- Ranked alerts by criticality

- Calculated glide range to nearest runways

- Outcome: Successful emergency landing

The Future of ECAM

- Generative AI Co-Pilots

Natural language processing for queries like *”Show worst-case fuel scenario if Engine 2 fails”* - Augmented Reality Overlays

Projecting engine diagrams onto maintenance panels during repairs - Predictive Wear Analytics

Vibration monitoring to schedule pre-failure replacements - Blockchain-Verified Updates

Tamper-proof software patches

ECAM FAQs

Q1: Can ECAM override pilot commands?

No. It’s advisory only. Pilots retain ultimate authority but risk tragedy if ignoring critical alerts.

Q2: How does ECAM differ from Boeing’s EICAS?

ECAM prescribes fixes (“DO THIS NOW”); EICAS describes faults (“ENGINE OIL PRESS LOW”). Airbus integrates checklists; Boeing pilots consult manuals.

Q3: What causes “ECAM overload”?

Cascading failures triggering multiple alerts. New systems use AI to cluster related faults.

Q4: Can ECAM function after total electrical failure?

Yes. Backup batteries power displays for 45+ minutes.

Q5: Why do mechanics value ECAM reports?

They pinpoint 90%+ of faults but require expertise to interpret technical codes.

Q6: Is ECAM vulnerable to hacking?

Multiple security layers include encrypted databases and mandatory dual-certified updates.

Q7: Does ECAM reduce pilot skills?

Regulators mandate “raw data” simulator training flying without automated aids.

Leave a comment