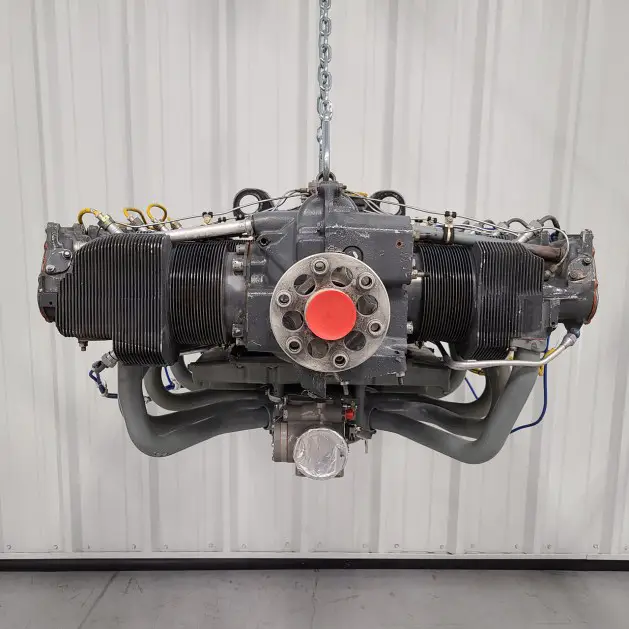

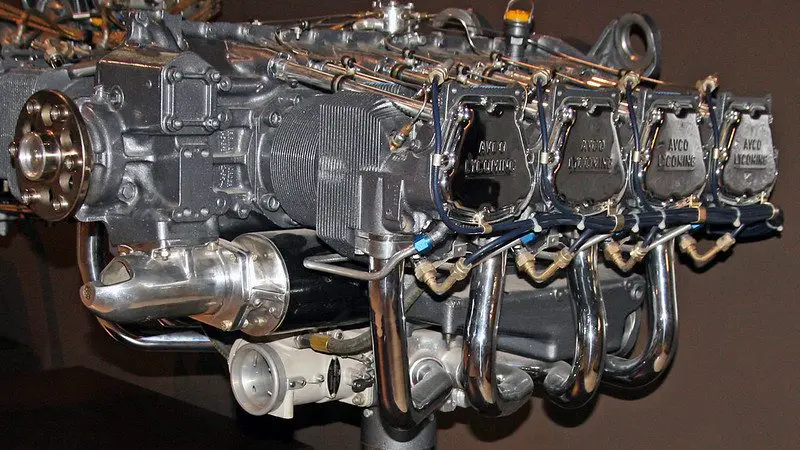

Lycoming IO-720 is a powerful, eight-cylinder, horizontally opposed aircraft engine renowned for its high performance and reliability. This engine is particularly suited for high-performance, heavy aircraft, providing substantial power and efficiency.

This guide provides an in-depth look at the Lycoming IO-720, including its history, design, specifications, variants, and applications.

History and Development

The Lycoming IO-720 was developed to meet the demands for a more powerful engine capable of handling larger and heavier aircraft.

Introduced in the early 1960s, it built upon the design principles of the smaller six-cylinder engines, extending Lycoming’s engine family with more cylinders and greater displacement to deliver higher power outputs.

Lycoming IO-720 Design and Features

The IO-720 engine features a robust and reliable design, incorporating advanced engineering principles for enhanced performance. Key design elements include:

- Configuration: Horizontally opposed eight-cylinder

- Cooling System: Air-cooled

- Displacement: 720 cubic inches (11.8 liters)

- Fuel System: Fuel-injected for improved efficiency and performance

- Ignition System: Dual magnetos for redundancy and reliability

- Lubrication System: Wet sump for consistent lubrication

Lycoming IO-720 Specifications

Here are the general specifications for the Lycoming IO-720 engine:

| Specification | Details |

|---|---|

| Manufacturer | Lycoming Engines |

| Model | IO-720 Series |

| Configuration | Horizontally opposed 8-cylinder |

| Displacement | 720 cubic inches (11.8 liters) |

| Bore x Stroke | 5.125 in x 4.375 in (130.2 mm x 111.1 mm) |

| Compression Ratio | 8.5:1 |

| Power Output | 400 hp (298 kW) |

| Fuel Type | Aviation gasoline (100LL) |

| Fuel System | Fuel-injected |

| Ignition System | Dual magnetos |

| Weight | 597 lbs (271 kg) (dry weight) |

If you are interested you should read about the Piper PA-24 Comanche

Lycoming IO-720 Performance

The Lycoming IO-720 engine series includes several variants, each tailored to specific performance and operational requirements:

- IO-720-A1A:

- Power Output: 400 hp at 2,650 RPM

- Notable Features: Standard fuel-injected version

- TIO-720-A1A:

- Power Output: 400 hp at 2,650 RPM

- Notable Features: Turbocharged for improved high-altitude performance

Applications

The Lycoming IO-720 engine is used in various high-performance aircraft, including:

- Piper PA-24-400 Comanche: Known for its speed and range, utilizing the IO-720 to achieve high performance.

- Aero Commander 500: A twin-engine aircraft benefiting from the power and reliability of the IO-720.

- Various Experimental and Homebuilt Aircraft: Favored by builders seeking high power output for custom designs.

Maintenance and Performance Upgrades

Maintaining the Lycoming IO-720 engine involves regular inspections and servicing to ensure longevity and performance. Key maintenance tasks include:

- Oil Changes: Regular oil changes are essential for engine health.

- Spark Plug Replacement: Ensuring efficient ignition and combustion.

- Magneto Inspection and Servicing: Crucial for reliable ignition.

- Fuel System Maintenance: Keeping the fuel injection system clean and functional.

- Cylinder Inspections: Checking for wear and proper operation.

For those looking to enhance performance, various aftermarket parts and upgrades are available:

- High-Compression Pistons: Increase power output by raising the compression ratio.

- Electronic Ignition Systems: Improve reliability and efficiency compared to traditional magnetos.

- Lightweight Starters and Alternators: Reduce weight and improve starting performance.

- Exhaust Systems: Performance exhaust systems can enhance power output and reduce weight.

Lycoming IO-720 Overhaul Cost

Overhauling a Lycoming IO-720 engine is a significant investment. The cost and time required for an overhaul can vary based on several factors:

- Cost:

- Professional Overhaul Shop: $35,000 to $50,000

- In-House Overhaul (if applicable): $30,000 to $45,000 (lower labor costs but requires specialized tools and expertise)

- Time:

- Professional Overhaul Shop: 8 to 12 weeks

- In-House Overhaul: 10 to 16 weeks (depending on availability of tools, parts, and expertise)

Lycoming IO-720 Price

New Engines

- New Lycoming IO-720: $70,000 to $90,000

Rebuilt Engines

- Factory-Rebuilt IO-720: $50,000 to $70,000

- Rebuilt engines are disassembled, inspected, and reassembled with new or reconditioned parts to meet or exceed original specifications.

Overhauled Engines

- Professionally Overhauled IO-720: $40,000 to $60,000

- Overhauled engines are disassembled, inspected, repaired, or replaced with necessary parts and then reassembled to return to service.

Used Engines

- Used Lycoming IO-720: $30,000 to $50,000

- Used engines are sold as-is and may require additional work or an overhaul to reach optimal condition.

Factors Influencing Price

Several factors can influence the price of a Lycoming IO-720 engine, including:

- Specific Model and Variant: Different variants of the IO-720 series have different power outputs and features.

- Condition: New, rebuilt, or overhauled engines have varying levels of reliability and remaining service life.

- Accessories and Modifications: Engines with upgraded accessories or modifications (e.g., electronic ignition systems, lightweight components) may command higher prices.

- Documentation and Warranty: Engines with complete maintenance records and warranties are typically more valuable.

Additional Costs

- Shipping and Handling: $300 to $600 depending on location and shipping method.

- Installation: Labor costs for installation can vary widely but generally range from $2,000 to $6,000.

- Accessories: Additional costs for components such as exhaust systems, starters, alternators, and fuel systems if not included.

FAQs

1. What is the Lycoming IO-720 engine?

The Lycoming IO-720 is a horizontally opposed, eight-cylinder, fuel-injected aircraft engine designed for high-performance, heavy-duty applications. It’s commonly used in larger aircraft, such as agricultural planes and high-performance twins.

2. What is the horsepower rating of the Lycoming IO-720?

The Lycoming IO-720 typically produces 400 horsepower at 2,650 RPM, making it one of the most powerful general aviation piston engines.

3. What aircraft commonly use the Lycoming IO-720?

Some popular aircraft models equipped with the IO-720 include:

- Piper PA-36 Pawnee Brave

- Aero Commander 680 series

- Agricultural and utility aircraft

4. What does “IO” in IO-720 mean?

- I: Fuel-Injected – The engine uses fuel injection instead of a carburetor for fuel delivery.

- O: Opposed – The engine has a horizontally opposed cylinder configuration for better balance and aerodynamics.

5. What are the dimensions of the Lycoming IO-720?

- Length: Approximately 44.6 inches.

- Width: Approximately 36.8 inches.

- Height: Approximately 25.6 inches.

These compact dimensions allow for effective installation in a wide range of aircraft.

6. How much does the Lycoming IO-720 weigh?

The engine has a dry weight of approximately 597 lbs, making it heavier than smaller Lycoming models but suitable for high-performance aircraft.

7. What is the average price of a new Lycoming IO-720 engine?

A new Lycoming IO-720 engine typically costs between $85,000 and $120,000, depending on the specific variant and additional features.

8. How much does an overhauled Lycoming IO-720 cost?

An overhauled Lycoming IO-720 can range from $50,000 to $70,000, depending on the overhaul service provider and the extent of the work done.

9. What is the Time Between Overhaul (TBO) for the Lycoming IO-720?

The recommended TBO for the IO-720 is approximately 1,800 to 2,000 hours, depending on the operating conditions and maintenance history.

10. What are the key advantages of the Lycoming IO-720?

- High power output: Ideal for larger and high-performance aircraft.

- Fuel injection: Provides efficient fuel delivery and reduces carburetor icing risk.

- Durability: Built for long-lasting reliability under demanding conditions.

11. What type of fuel does the Lycoming IO-720 use?

The engine typically runs on 100LL (low lead) aviation gasoline, though newer variants may accommodate unleaded aviation fuels.

12. What is the compression ratio of the Lycoming IO-720?

The compression ratio of the IO-720 is 8.7:1, which contributes to its high performance while maintaining fuel efficiency.

13. Can the Lycoming IO-720 be turbocharged?

Yes, some variants of the IO-720 are turbocharged (denoted as TIO-720), enhancing performance at high altitudes and increasing power output.

14. What is the difference between the IO-720 and the TIO-720?

The TIO-720 is a turbocharged version of the IO-720, providing additional power and improved high-altitude performance. However, the TIO-720 may require more maintenance due to the turbocharging system.

15. What are the maintenance considerations for the IO-720?

Regular maintenance includes:

- Oil changes every 50-100 hours.

- Compression tests to ensure cylinder health.

- Fuel system inspections for injectors and pumps.

- Periodic valve adjustments to maintain efficiency.

16. How is the Lycoming IO-720 cooled?

The IO-720 is air-cooled, using ram air to dissipate heat generated during operation, reducing complexity compared to liquid-cooled systems.

17. Is the Lycoming IO-720 suitable for aerobatics?

While it provides significant power, the IO-720 is not specifically designed for aerobatic aircraft due to its weight and size.

18. How does the IO-720 compare to other Lycoming engines?

- IO-540: The IO-720 offers greater power but is heavier.

- O-360: The IO-720 provides much higher performance but at the cost of increased weight and fuel consumption.

19. Can the Lycoming IO-720 run on automotive fuel?

While primarily designed for aviation fuel, some variants can be modified to use automotive fuel, provided proper approvals and modifications are made.

20. What are common issues with the Lycoming IO-720?

- Cylinder wear: Due to high power output.

- Fuel injector maintenance: Requires regular cleaning to prevent clogs.

- Oil leaks: Common in older engines if not properly maintained.

21. How often should spark plugs be replaced in the IO-720?

Spark plugs should be inspected and cleaned every 100 hours and replaced as needed, typically every 200-300 hours.

22. What is the typical fuel consumption of the IO-720?

The IO-720 consumes approximately 24-28 gallons per hour (GPH) at cruise settings, depending on power settings and altitude.

23. Can I upgrade an older IO-720 engine?

Yes, older IO-720 engines can often be upgraded with:

- Modern fuel injection systems.

- Advanced ignition systems, such as electronic ignition.

- Lightweight components to reduce overall weight.

Leave a comment