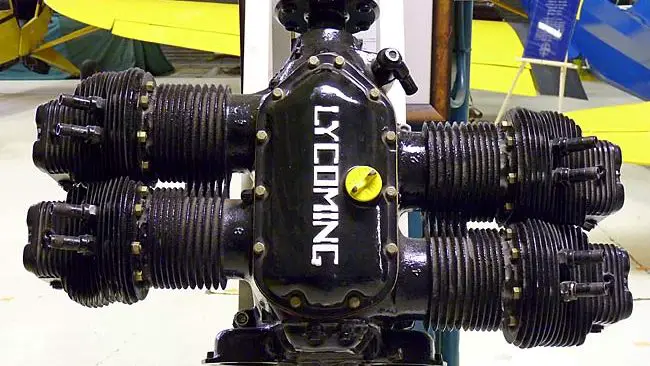

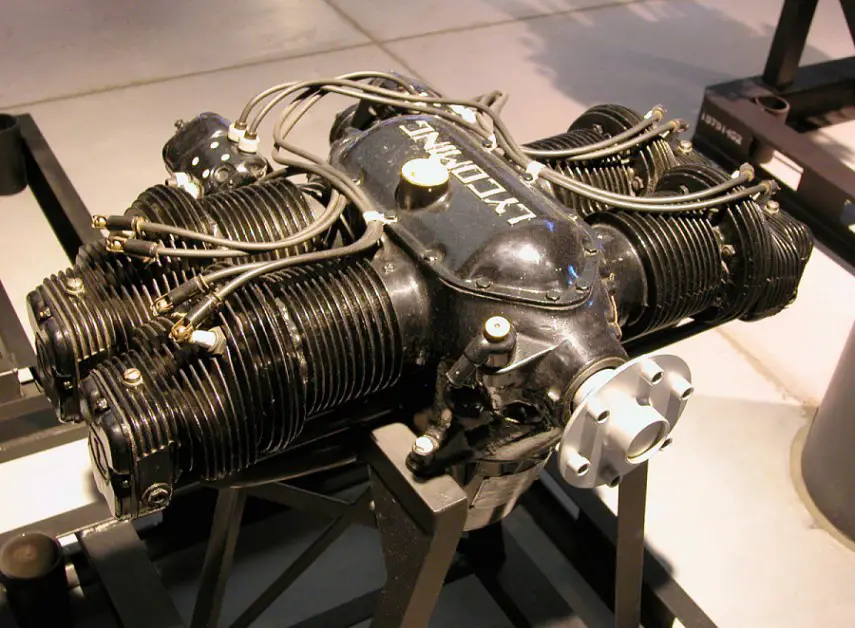

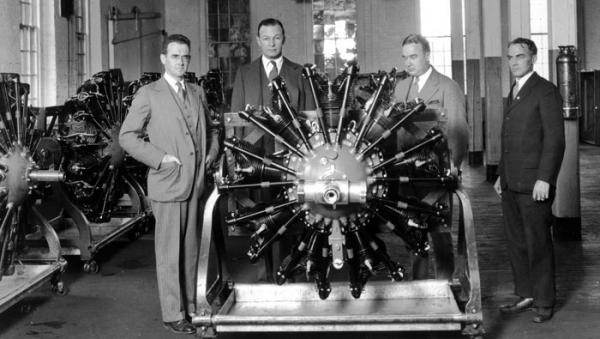

The Lycoming O-145 is a small, four-cylinder, air-cooled, horizontally opposed engine designed and produced by Lycoming Engines. Introduced in the 1930s, the O-145 engine series was developed to power light aircraft. This article explores the specifications, performance, applications, and legacy of the Lycoming O-145 engine.

Specifications of the Lycoming O-145

Here are the key specifications of the Lycoming O-145 engine:

| Specification | Value |

|---|---|

| Configuration | Horizontally opposed 4-cylinder |

| Displacement | 145 cubic inches (2.38 liters) |

| Bore | 3.625 inches (92.08 mm) |

| Stroke | 3.50 inches (88.90 mm) |

| Compression Ratio | 6.3:1 |

| Power Output | 55-75 horsepower (41-56 kW) |

| RPM Range | 2,300 to 2,550 RPM |

| Fuel System | Carbureted |

| Cooling System | Air-cooled |

| Ignition System | Dual magneto |

| Dry Weight | 195-200 lbs (88-91 kg) |

| Fuel Type | 80/87 octane aviation gasoline |

| Oil Capacity | 4 quarts (3.8 liters) |

If you are interested you should read about the Piper PA-15 Vagabond

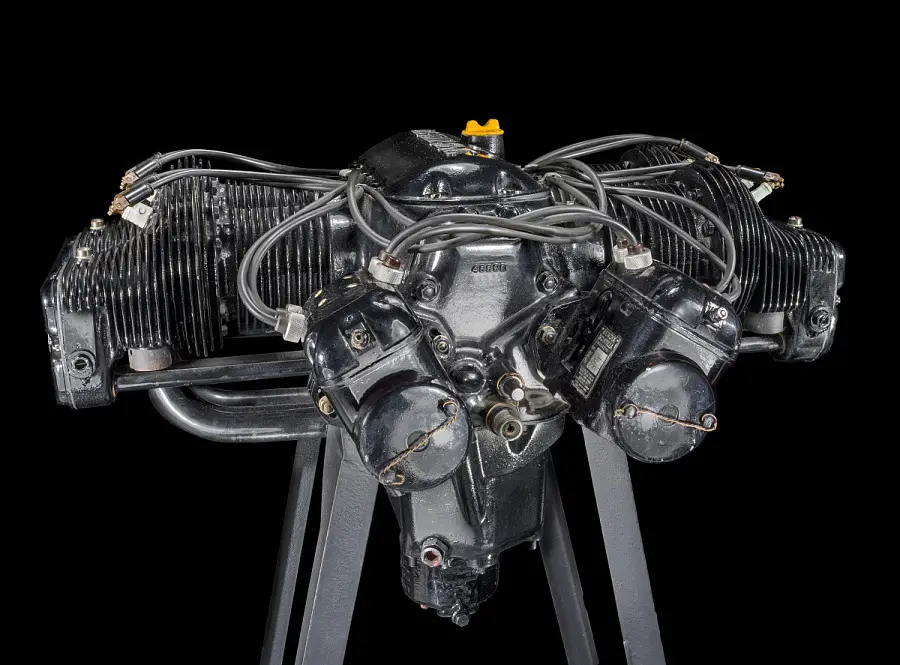

Lycoming O-145 Performance Characteristics

The Lycoming O-145 offers a range of performance characteristics suitable for light aircraft:

- Power Output: The engine produces between 55 and 75 horsepower, depending on the specific model and configuration. This power range is sufficient for many light aircraft applications.

- Fuel Efficiency: The O-145 is relatively fuel-efficient, making it economical to operate.

- Durability: The engine’s air-cooled design and robust construction contribute to its longevity and reliability.

- Lightweight: With a dry weight of approximately 195-200 lbs, the O-145 is light, which helps improve aircraft performance and handling.

Lycoming O-145 Variants

The O-145 engine series includes several variants, with the most common being:

- O-145-A: Produces 55 horsepower at 2,300 RPM.

- O-145-B: Produces 65 horsepower at 2,550 RPM.

- O-145-C: Produces 75 horsepower at 2,550 RPM.

Lycoming O-145 Applications

The Lycoming O-145 engine has powered a variety of light aircraft, reflecting its versatility and reliability. Notable applications include:

- Piper J-3 Cub: The O-145 engine was used in some models of the iconic Piper J-3 Cub, providing reliable power for this popular trainer and recreational aircraft.

- Taylorcraft BC-12D: Another classic light aircraft, the Taylorcraft BC-12D, utilized the O-145 engine in some configurations.

- Stinson 108: The Stinson 108, a post-war light aircraft, also saw some use of the O-145 engine.

Lycoming O-145 Maintenance and Restoration

For those interested in maintaining or restoring aircraft equipped with the Lycoming O-145, here are some key considerations:

- Parts Availability: While the O-145 is no longer in production, many parts are still available through specialized suppliers and vintage aircraft parts dealers.

- Overhaul Services: Several companies and independent mechanics specialize in overhauling vintage aircraft engines, including the O-145. Overhauling an engine typically involves disassembly, cleaning, inspection, and replacement of worn components.

- Documentation: Having comprehensive maintenance and overhaul records is crucial for ensuring the engine’s continued reliability and airworthiness.

Lycoming O-145 Price

New or Overhauled Engines

- New Engines: Finding a brand-new Lycoming O-145 engine is highly unlikely since these engines are no longer in production. However, in rare cases, new old stock (NOS) engines may appear. These could be priced very high, potentially upwards of $20,000 or more.

- Overhauled Engines: Overhauled Lycoming O-145 engines are more common. These engines have been disassembled, cleaned, inspected, and reassembled with new or refurbished parts to restore them to good working condition. The price for an overhauled O-145 engine typically ranges from $10,000 to $15,000, depending on the quality of the overhaul and any included warranties.

Used Engines

- Good Condition: Used Lycoming O-145 engines in good, serviceable condition can be priced between $5,000 and $10,000. These engines are generally flyable but may not have the same warranty or service life as an overhauled engine.

- Fair Condition/Project Engines: Engines that are in fair condition or considered project engines (requiring significant work to become airworthy) can be found for $2,000 to $5,000. These engines may need substantial investment in terms of parts, labor, and expertise to restore.

Lycoming O-145 Parts and Components

- Individual Parts: For those looking to repair or rebuild an existing Lycoming O-145 engine, individual parts can be sourced from specialized suppliers. Prices for parts vary widely depending on the specific component and its condition. Common parts like cylinders, pistons, and carburetors can range from a few hundred to several thousand dollars.

- Rebuild Kits: Complete rebuild kits, which include a comprehensive set of parts needed for an overhaul, can cost between $3,000 and $6,000, depending on the supplier and the completeness of the kit.

Leave a comment